PGI GEOTHERMAL Heating and Cooling Systems

Discover the Comforts of Smarter Living

Geothermal Heating and cooling Systems

An investment in a Hydron geothermal system provides an array of benefits not found with other systems.

PGI Geothermal Systems

P.O. Box 1236, Melville, NY 11747 – Tel: 516-840-9121

Geothermal Heating and cooling Systems

An investment in a Hydron geothermal system provides an array of benefits not found with other systems.

PGI Geothermal Systems

P.O. Box 1236, Melville, NY 11747 – Tel: 516-840-9121

|

PGI’s Geothermal Systems

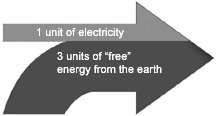

What is a Geothermal Heat Pump? Geothermal Systems (GSHPs) are electrical powered units that tap the stored energy of the greatest solar collector in existence, the Earth. These systems utilize Earth's relatively constant temperature to provide heating, cooling and hot water for homes and commercial buildings. How do Ground Source Heat Pumps Work? Ground source heat pumps are categorized as 'open' (well water) or 'closed' loops. These two choices generally are the types used here on Long Island. On Long Island, an open well water system is most common and most efficient because our ground water is about 55 degrees F all year round. This only requires about a three foot area for drilling the supply well and the return (dispersion) well. The latter is generally on the opposite side of the home and can be used for new or old construction. Alternatively, a closed loop horizontal slinky type pipe can be installed. However, the closed loop system is generally only used in new construction homes because of the need to dig multiple trenches six feet deep, 100 to 125 feet long. You need one loop per ton on Long Island. Local soil conditions effect efficiency. For closed loop systems, water or antifreeze solution is circulated through plastic pipes buried beneath the Earth's surface. During the winter, the fluid collects heat from the Earth and carries it through the system and into the home/building. During the summer, the system reverses itself to cool the building by extracting heat from the home/building and the Geothermal system passes it to the well water or closed loop that allows the Earth to absorb the heat. Whether using an open or closed loop, the Geothermal heat pump system creates virtually free hot water all year round through an optional de-superheater heat exchanger contained in the Geothermal heat pump. Lower Operating Cost: A geothermal system operates more efficiently than ordinary heating and air conditioning systems because they can deliver an astounding four units of energy for every one unit of electrical energy used. That translates into an efficiency rating of 400 percent, compared to the most efficient gas furnace, which rates only 94 percent. By combining stored earth energy with safe electric power, the EPA has stated that homeowners realize savings of 30 to 70% on heating and 20 to 50% on cooling. The ground absorbs about 47% of the sun’s energy. Geothermal systems harness that free, renewable energy, providing an environmentally friendly way to heat and cool your home. Installing a Geothermal system is the environmental equivalent of planting 775 trees or removing two cars from the road. The Hydron system does not burn fossil fuel which means no emissions or harmful greenhouse gases are released into the air. Enhanced Comfort: Provides precise distribution of comfortable air all year long, eliminating hot spots and cold spots. During heating, you’ll experience warm air without the hot blasts associated with ordinary gas furnaces. Leave the thermostat at whatever comfort level you desire and the Geothermal system with its variable speed blower will provide precise control and comfort levels. Safe: Because natural gas, propane or oil are not required to operate a geothermal unit, there’s no combustion, flames or fumes and no chance of carbon-monoxide poisoning. Quiet: Unlike ordinary air conditioners or heat pumps, there is no noisy outdoor unit to disturb your outdoor environment or your neighbors. Geothermal units are designed and constructed for “whisper quiet” operation, similar to your refrigerator. Most models include variable speed fan motors and acoustical stainless steel enclosures for ultra quiet operation. Reliable: Unlike air conditioners and heat pumps, geothermal units are installed indoors (like your refrigerator), so they are not subject to wear and tear caused by rain, snow, ice, debris, extreme temperatures or vandalism. Geothermal units have proven to be very reliable and require less maintenance. Hot Water Mode: Most geothermal units installed in homes have an optional feature called a Desuperheater. This component consists of are fragrant-to-water heat exchanger installed at the discharge of the compressor. The hot gas at this point is in a “superheated” condition. In the Desuperheater, the refrigerant releases some of the heat into the cooler water through the copper wall of the Desuperheater heat exchanger. A small circulator moves the water from the water transferred to the water. Let’s Get Technical The Interesting Basics... Geothermal units utilize some of the same technology found in your home’s refrigerator. They are both devices that move heat energy. A refrigerator removes heat from food. A geothermal system removes heat energy from the earth to heat your home and removes heat energy from inside your home to cool it. Both technologies rely on a scientific principle that states “energy (heat) flows spontaneously from an area of high concentration (hot body) to an area of low concentration (cold body).” Heat flows from hot matter to cold matter, never vice-versa. It is why ice cubes melt on a hot day, and why boiling water cools after you remove it from the stove. Energy/heat wants to naturally disperse, and it will do so unless hindered by an outside force. This applies to Geothermal heating and cooling systems. In nature, the ground serves as a giant solar collector storing heat energy a few feet below its surface. Here, temperatures remain very constant and moderate, unaffected by fluctuating outdoor temperatures. On Long Island, ground temperature at six feet is about 55 degrees F year round. Energy is exchanged using a series of pipes buried below the Earth’s surface (closed loop) or with well water (open loop). The latter is the most efficient installation on Long Island. Applying the principle stated, we know that in cold outdoor weather, the warmer Earth will release heat energy into the well water/cooler loop. This heat is absorbed from the warmed loop by water/cool refrigerant in the water-to-refrigerant heat exchanger contained in the Geothermal heat pump. Finally, the heat is released from the warmed refrigerant into the cooler house (via supply air ducts) by the air-to-refrigerant heat exchanger (air coil). As heat is drawn away from the Earth’s well water or loop to the house, the loop is cooled again to a point where its temperature is lower than the surrounding soil and the process repeats. During warm outdoor weather, the cooler Earth serves as a heat sink. Heat is absorbed from the house by the cool refrigerant in the air coil (via return air). The cool well water or loop water absorbs heat from the warmed refrigerant. This heat can also be diverted to create hot water if the optional desuperheater is utilized. Because the loop is now warmer than the cool Earth, the heat simply moves away from the loop into the cool Earth. The Boring Details... Heating Mode: During heating, a geothermal system absorbs the heat from the ground via the earth loop. The heating cycle starts as cold, liquid refrigerant passes through the water-to-refrigerant heat exchanger. The heat exchanger is made of copper and consists of a tube within a tube—water from the loop travels through one tube (the inside tube), refrigerant passes through the other (outer) tube. As the loop fluid flows through the heat exchanger, the heat energy transfers from the loop fluid to the refrigerant through the copper wall separating the two. This heat transfer causes the cold liquid refrigerant to turn into a gas. Unlike water, refrigerant changes from a liquid into a gas at a very low temperature. The gaseous refrigerant is sucked into the compressor where it is compressed. After compression, the refrigerant will be very hot (approx. 165° F) and is discharged through the reversing valve and into the air coil. The air coil is a radiator-like device that has thin aluminum “fins” attached to the copper refrigerant tubing. The refrigerant passes through the air coil (the condenser during heating). As air from this return air duct system passes over the air coil, heat is released from the refrigerant and absorbed by the cooler air. Environmentally Friendly: According to the Department of Energy and the EPA, geothermal systems are the most environmentally friendly way to heat and cool your home. The system emits no carbon dioxide, carbon monoxide or other greenhouse gasses which are considered to be major contributors to environmental air pollution. With a geothermal system, you can take comfort in a better environment. In addition, the lower peak demand for geothermal systems helps to postpone the need to build more expensive electric generating plants. Flexible: Geothermal systems are installed in homes from the cold climate of northern Canada and Alaska to the heat of Florida and Texas. Whether your home is new or old, large or small, a geothermal system can deliver comfort. One compact unit provides heating, central air conditioning and domestic hot water. Various sizes, configurations (horizontal, vertical, splits), and options enable a system to be installed in virtually any application. Geothermal Water Source Heat Pump PGI recommends Hydron because of their advanced state of the art, built tough construction which integrates the highest quality modules coupled with an intelligent diagnostic electronic monitoring system for maximum reliability. Heating Cycle The heating process involves the extraction of heat energy from the ground |

Hydron R410 Series Features:

- Dual Speed Compressor - Variable Speed ECM Blower Motor - Stainless Steel Construction - Cupro-Nickel Heat Exchanger - Optional domestic Hot Water Desuperheater - Available in sizes for 1.5 to 12 ton capacities Open Loop

Well water is used as the ground source for heating and cooling. After passing through the heat pump to extract heat from the earth or return heat to the earth the well water is returned to the ground in a Diffusion well. Horizontal Slinky Alternatively, a closed loop can also be utilized. In this installation, a trench is dug with a backhoe several feet deep and about 3 feet wide. The coils are “layed off” and spaced evenly throughout the length of the trench. Think of a flattened, stretched out slinky toy. Slinkys can be designed as ‘compact’ or ‘extended.’ Trench lengths are typically 100 to 150 feet long and a loop is needed for each ton. Generally, this type of system is less efficient on Long Island due to its sandy soil conditions.

4 units of heating or cooling delivered into home

Energy Efficient The result is warm air (typically 95° to 105° F) which is delivered through the duct system by the blower. The refrigerant, now cooled again, passes through the expansion valve which acts as a flow control, returning to the heat exchanger where it can accept more heat from the warmer loop fluid. This process is continuous during the heating mode. Cooling Mode: During cooling, a Geothermal system rejects the heat from the indoor air into the Earth loop. The cooling cycle starts as cold, liquid refrigerant passes through the air coil (the evaporator during cooling). As the refrigerant flows through the air coil, the heat energy transfers from the warm return air to the refrigerant. This heat transfer causes the cold liquid refrigerant to turn into a gas. The compressor draws the refrigerant gas, compresses it and discharges it through the reversing valve. During cooling, the reversing valve is energized which changes the openings from one port to another, causing the refrigerant flow to go in the opposite direction that it was in the heating mode. However, the flow to the compressor does not change direction. After compression, the hot refrigerant passes through the heat exchanger (the condenser during cooling). In the heat exchanger, the hot refrigerant releases its’ heat energy to the cool loop fluid through the copper walls. Now, cooled and liquefied, the refrigerant passes through the expansion valve back to the air coil. Warm air passing over the cool air coil causes the air to be cooled and dehumidified. This process is continuous during the cooling mode. Red = Warm Blue = Cool

Optional Desuperheater - Hot Water Mode: Most Geothermal units installed in homes have an optional feature called a desuperheater. This component consists of a separate refrigerant-to-water heat exchanger installed at the discharge side of the compressor. The hot gas at this point is in a "superheated" condition. In the desuperheater, the refrigerant releases some of the heat into the cooler water through the copper wall of the desuperheater heat exchanger. A small circulator moves the water from the water heater to the heat pump and back to the water heater. This excess hot gas is available in both the heating and cooling modes. However, there is a greater hot water benefit during cooling because some of the heat that is extracted from the air ends up in the superheat and is transferred to the water. The amount of hot water generated in a function of the run time of the unit. On very hot days and cold days, the desuperheater may be able to generate the majority of the hot water required for the home due to the long run times of the unit. On milder days when the unit has short duty cycles, the gas, oil or electric contained in the primary hot water heater storage tank will maintain the desired temperature so there will always be enough hot water. A safety device (sensor) shuts off the circulator for the desuperheater in the event the water temperature reaches 125 to 130 degrees F. As you will see, the desuperheater supplies heated water that only has to be raised by 10 to 15 degrees F. Installing a second tank that is sized for the family and used as a storage tank, provides very substantial reductions in fuel costs. The amount of hot water generated is a function of the run time of the unit. On very hot days and cold days, the desuperheater may be able to generate the majority of the hot water required for the home due to the long run times of the unit. On milder days when the unit has short duty cycles, the electric elements in the water heater will maintain the desired temperature so there will always be enough hot water. A safety device (sensor) shuts off the circulator for the desuperheater in the event that the water temperature reaches 130° F. The heating process involves the extraction of heat energy from the ground, and moving it into the building. Transferring the heat from the earth to the building involves a cycle of evaporation, compression, condensation and expansion. A refrigerant is used as the heat transfer medium. The heating cycle starts as cold, liquid refrigerant passes through a water-to-refrigerant heat exchanger and absorbs heat from the water (earth loop fluid or well water). The refrigerant evaporates into a gas as heat is absorbed. The gaseous refrigerant passes through a compressor where the refrigerant is pressurized, raising its temperature to over 180° F. The hot gas then circulates through a refrigerant-to-air heat exchanger where heat is removed as the cooler return air passes over it. Now heated, this warm air is delivered into the building by way of the blower and the duct system. Upon releasing its heat energy into the air, the refrigerant returns to the water-to-refrigerant heat exchanger where the process is repeated continuously during the heating process. The hot refrigerant produces hot water that is delivered to the water heater by way of a small pump. The cooling process involves the extraction of heat energy from the air in the building, and moving it into the earth. Transferring the heat from the air in the building to the earth involves a cycle of expansion, condensation, compression, and evaporation. A refrigerant is used as the heat transfer medium. The cooling cycle starts as the compressor delivers refrigerant to the water-to-refrigerant heat exchanger. Heat from the refrigerant is absorbed by (rejected into) the low temperature source (earth loop fluid or well water) resulting in the refrigerant turning cold. The cold refrigerant passes through a refrigerant-to-air heat exchanger. As warm, humid air from the return air duct system is passed over the cold air coil, the air is cooled and dehumidified the returned into the building, cooling the space. The heat from the warm air that returns to the unit is absorbed by the cold refrigerant, turning the refrigerant into a warm gas. The hot refrigerant is returned to the compressor where the process is repeated continuously during the cooling process. A portion of the heat returning to the compressor (from the hot return air) is diverted to another refrigerant circuit that generates hot water and delivers it to the water heater by way of a small pump. Geothermal Hydron systems are rated number one in energy efficiency because they can deliver an outstanding four units of energy for every unit of electrical energy used. Compare that to even the best ordinary system that delivers less than one unit of energy for every unit it consumes. That translates into an efficiency rating of 400 percent, compared to the most efficient gas boiler or water heater, which rates around 90 percent. Cooling Cycle Example of how the cooling cycle works |