|

Kitchen Range Exhaust

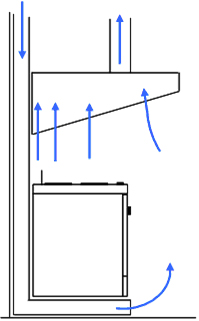

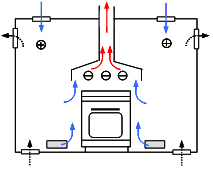

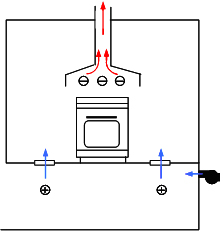

Capture the Effluent. The first thing we make sure is that the exhaust hood actually works to capture the effluent. The hood must overhang the cooking surface big-time. The absolute best approach is to use a backshelf hood with side panels and large overhangs on both sides and the front. backshelf hood can typically use 30% less exhaust to capture bad stuff compared to other hoods. Side panels can get you another 30% improvement. Note the direct makeup air using a modified backwall approach such that this makeup air is introduced at floor level. The direct makeup air introduced at floor level should never provide more than 60% to 70% of the hood exhaust. Why? Ah, we need a zone of negative pressure around the cooking surface. You don't want to push the bad stuff; you want to pull the bad stuff. Satisfaction. We satisfy 60% to 70% of the makeup air requirement with the modified backwall approach introducing air at floor level (the "blue arrows" at the lower grilles on each side of the appliance). We now provide a second system that meets the rest-plus a little bit (around 350 to 400 cfm), and this air is typically preconditioned and introduce at the ceiling at the perimeter of the kitchen area (the "blue arrows" coming from the two ceiling registers). We "suck" at the center of the space at the appliance and "below" at the perimeter. The exhaust hood and the two makeup air systems are interlocked. When they are operating the rest of the house does not know they are there. We, in essence, have uncoupled the kitchen from the rest of the building HVAC systems (the "black dashed arrows" entering from the floor registers and leaving up high on the wall). We condition the kitchen cooking area with the house HVAC system pretending that the cooktop/oven and range hood are not there. Smaller Hood Are Easier. With a 200 cfm kitchen range hood, we interlock the range hood exhaust with a supply fan that provides makeup air at roughly a 10% greater flow rate than the hood exhaust rate. This makeup air is typically provided in a separate zone like a basement that provides ample tempering of the makeup air by mixing. It than is introduced via floor registers adjacent the cook surface. The zone around the appliance needs to "suck" but the rest of the space blows or is neutral. The 10% greater flow rate works because this air is not directly introduced under the appliance but into the adjacent zone and moves into the cooking area as transfer air. |

|

|